FOR YOU:

DESIGN AND ENGINEERING ACTIVITIES

Based on your goals, conditions and allocated budget, we will efficiently and quickly conduct a comprehensive analysis of the project, develop technical and project documentation, and help you draw up a calendar plan for the supply of equipment and performance of work.

You can contact us if you need industrial and research vacuum installations developed taking into account the latest world achievements in the field of vacuum technology.

You have at your disposal the knowledge and experience of certified design engineers with specialized higher education, as well as extensive experience in designing and working with modern vacuum technology.

Knowledge, experience and the use of the latest technologies allows us to create equipment that best meets your requirements in terms of technical characteristics, quality and reliability.

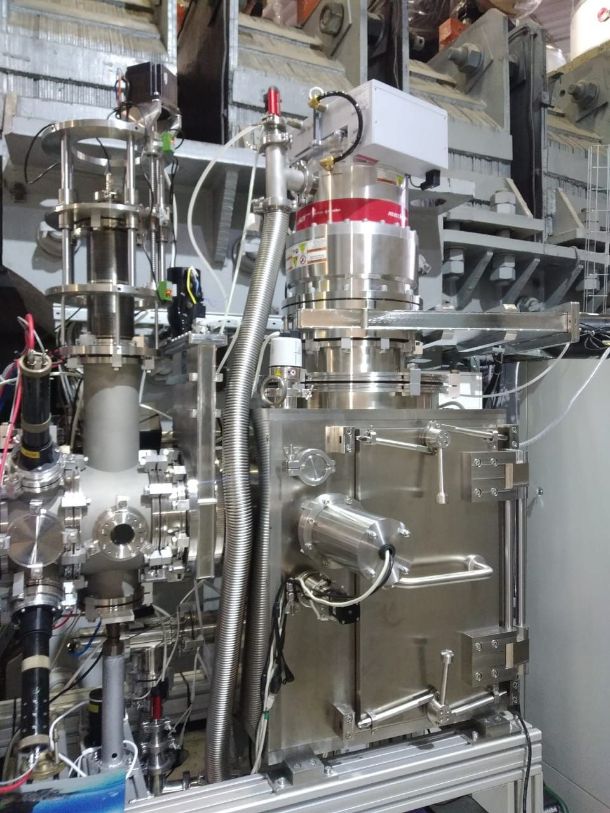

Our company has considerable experience and has earned an excellent reputation in the design and manufacture of the following types of equipment:

- space simulation installations;

- high vacuum pumping stations for various applications;

- various scientific, research and experimental vacuum installations.

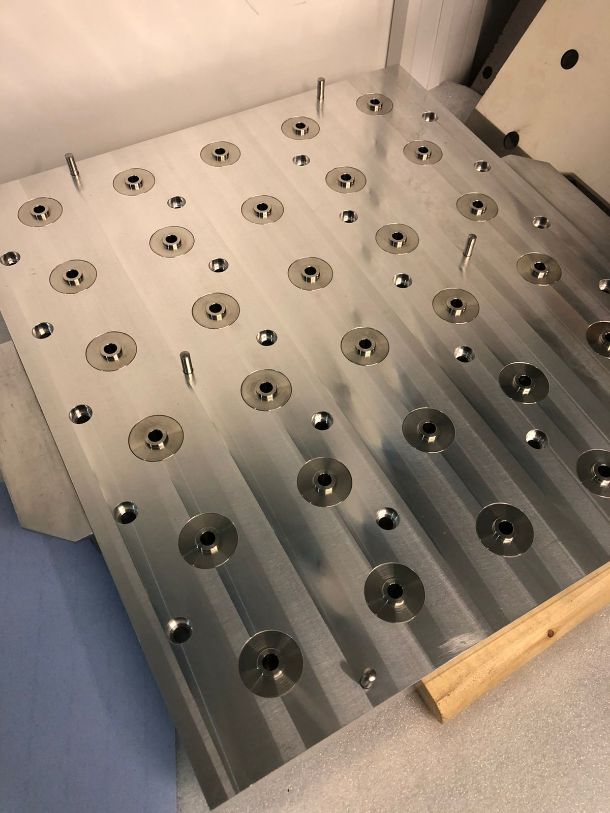

MODELING AND PRODUCTION OF VACUUM SYSTEMS

The calculation of the vacuum system is often carried out in two stages. At the first stage, a design calculation is carried out to determine the approximate scheme of the vacuum system. The types and capacities of pumps that are responsible for pumping the working space to the required pressure are selected. Depending on the main pumps, additional pumps and pre-dilution devices are selected. The estimated dimensions of pipes for vacuum systems, connecting components, etc. are prescribed.

At the second stage, it is the turn of the calibration calculation, during which the exact parameters of pumps, the size of pipelines and connecting elements are determined. Depending on the final dimensions of the centralized vacuum system, the most efficient pumping rate is calculated. Taking into account the kinetics of gas release, the time to obtain the required pressure in the working chamber is calculated. If these kinetic calculations are not available, they are also performed at this stage.

In addition, taking into account the maximum residual pressure, the pressure of the pre-dilution unit, the kinetics of gas release, the change in the pump speed and pipe conductivity depending on the pressure, the pre-pumping time is calculated.

Vacuum technologies are in stable demand in a wide variety of industries, and both individual components and entire systems are used. The production of vacuum systems for specific customer requests allows industrial companies to obtain more effective tools for planning production processes and developing new areas of activity.

MAINTENANCE AND REPAIR OF VACUUM SYSTEMS

Vacuum systems with universal technical characteristics have found wide application in metallurgy, printing, chemical, textile, pulp and paper industry, automotive industry. The main purpose of the vacuum system is to create a vacuum and pump out vapors, process gases to the required pressure level.

The operation of vacuum systems in industrial production inevitably causes the loss of some technical characteristics due to wear of structural elements, bearings and seals. Timely maintenance of vacuum systems guarantees the extension of the operability of intensively operating industrial equipment operated in intensive mode.

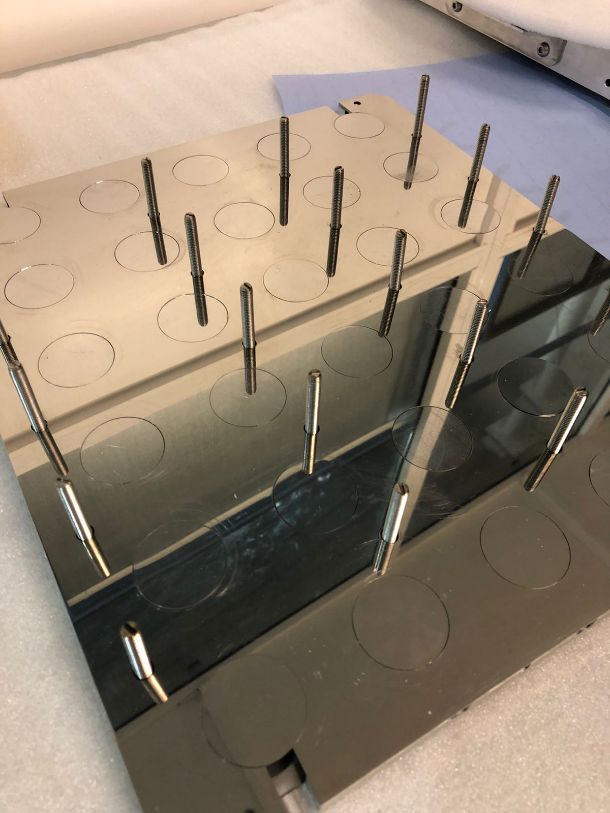

DEVELOPMENT AND PRODUCTION OF VACUUM TECHNOLOGICAL THIN-FILM EQUIPMENT AND HIGH-TECH PRODUCTIONS BASED ON IT.

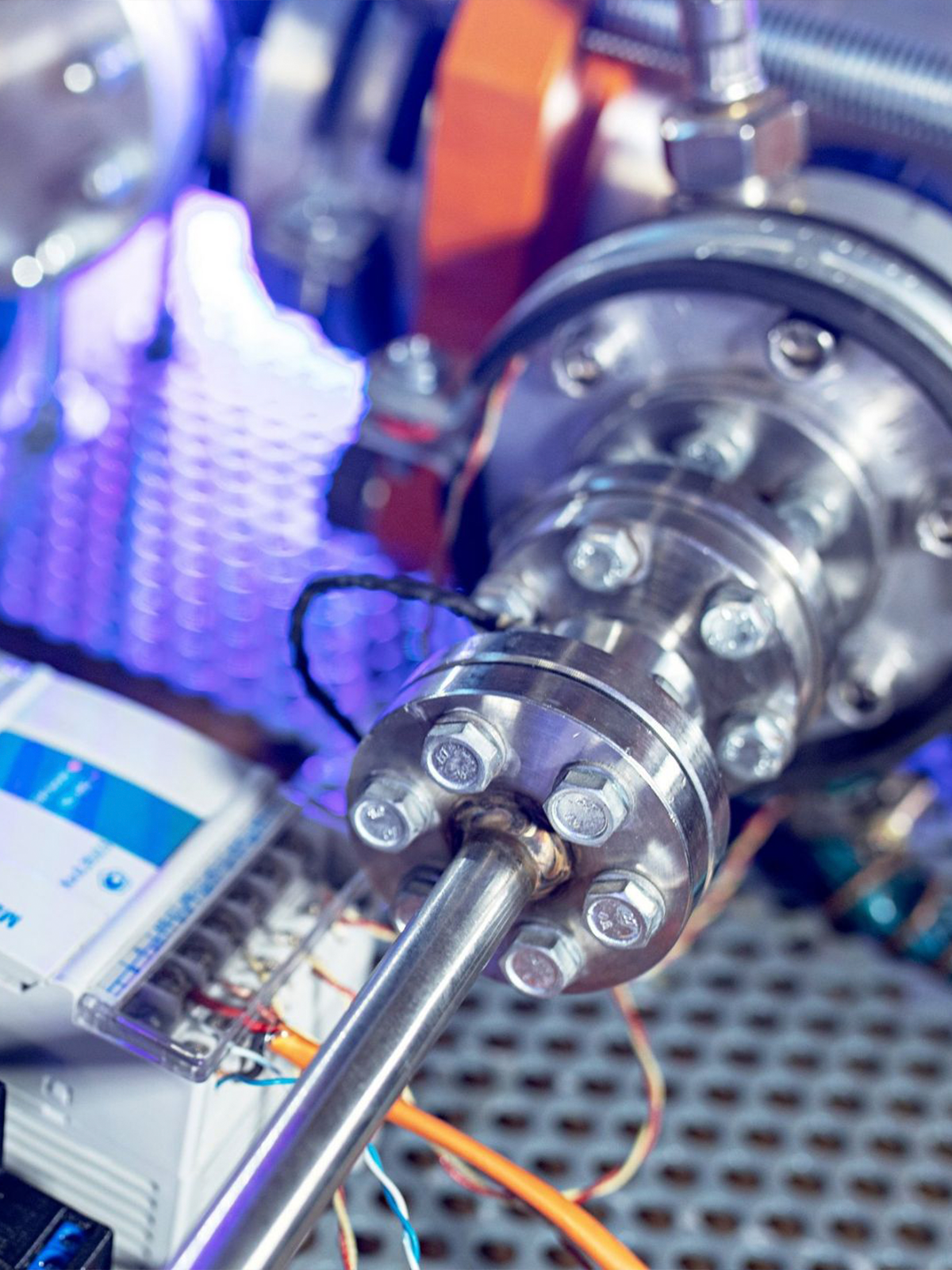

Services for the development and spraying of thin-film coatings for production and research. Our advantages. Many years of experience in applying thin films. Modern developments and innovations. Creating unique turnkey solutions. Making calculations and conducting research. Development and production of special vacuum technological thin-film equipment and high-tech productions based on it. The installations produced by our company are widely used in display manufacturing, microelectronics, optics and the space industry.

The VacuumTech team successfully develops innovative production systems for thin-film equipment. These systems make it possible to make the final product more cost-effective for the manufacturer and affordable for the consumer, while increasing the quality level and technical characteristics of the product.

SPRAYING OF THIN-FILM COATINGS

The company "Vakumtech" provides services for the application of magnetron coatings and ion nitriding of the Customer's products.

These services are provided at the company's pilot production facility that meets all the necessary requirements for modern vacuum coating production.

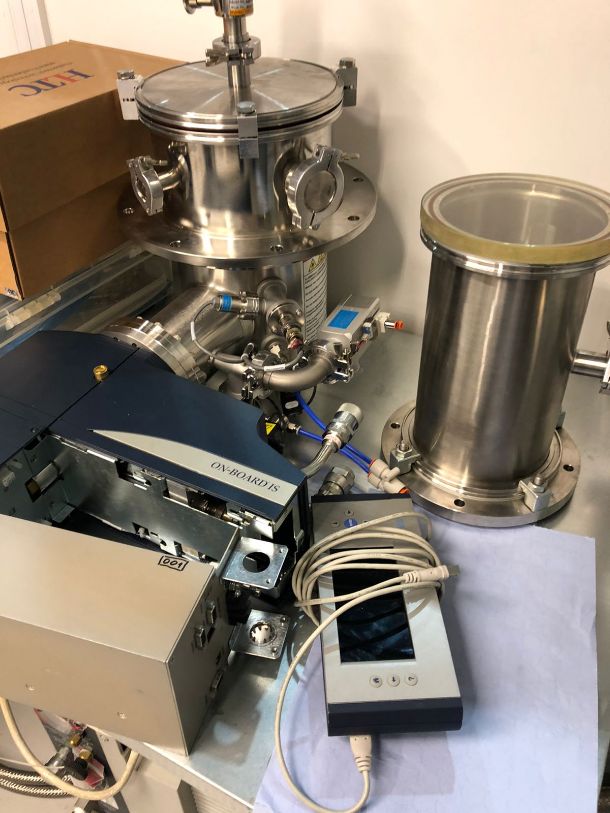

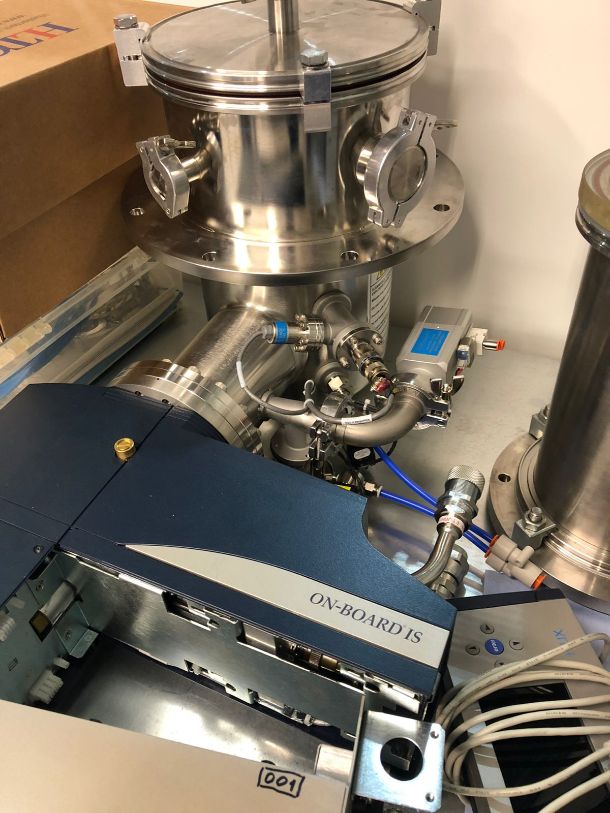

The pilot production includes:

— a coating site, including six vacuum installations of various types and functionality;

— site of chemical preparation of the surface of products

— laboratory for monitoring the properties and characteristics of coatings.

The technical and technological staff of the production has the highest professional qualifications.

In case of receiving a unique (non-standard) order, additional resources of the department of advanced technological developments are used.

To meet the technical requirements of the Customer, any magnetron PVD coating and nitriding technology from the entire range of technologies developed by Vakumtech can be used.

ABOUT US

The Vacuum Technologies Company (VacuumTech) is a developer and manufacturer of special vacuum technological thin–film equipment and high-tech productions based on it. The installations produced by our company are widely used in display manufacturing, microelectronics, optics, and the space industry.

The VacuumTech team successfully develops innovative production systems for thin-film equipment. These systems make it possible to make the final product more cost-effective for the manufacturer and affordable for the consumer, while increasing the quality level and technical characteristics of the product.

VacuumTech provides magnetron coating and ion nitriding services for the Customer's products.

These services are provided at the company's pilot production facility that meets all the necessary requirements for modern vacuum coating production.

The pilot production includes:

— a coating site, including six vacuum installations of various types and functionality;

— site of chemical preparation of the surface of products

— laboratory for monitoring the properties and characteristics of coatings.

The technical and technological staff of the production has the highest professional qualifications.

In case of receiving a unique (non-standard) order, additional resources of the department of advanced technological developments are used.

To meet the technical requirements of the Customer, any magnetron PVD coating and nitriding technology from the entire range of technologies developed by Vacuum tech can be used.

In case of difficulties with the choice of the necessary coating to solve a specific problem, the Customer may be offered a competent recommendation on the use of the most effective coating or ion nitriding technology to solve this problem.

The key advantage of our company is the combination of professional experienced management and scientific and technical competencies. This ensures consistently high quality of our products and related services. Individual development of solutions for each customer, flexible financing systems and project deadlines, control of logistics of manufactured equipment are possible thanks to effective management and personal responsibility of each employee. The company's team consists of managers, developers and technical staff, each of whom is a highly qualified professional in their field.

During the successful implementation of international projects for the production of equipment in the interests of the largest multinational corporations, our company's employees have gained unique experience for Kazakhstan and CIS countries in solving both standard and non-standard tasks in the field of development and maintenance of thin-film productions.

Many of the company's technical solutions were used for the first time. In this regard, Vacuum Tech is the copyright holder for a number of patented inventions and know-how used in the industry.

VacuumTech offers innovative engineering systems and ensures continuous monitoring of compliance with technical requirements at all stages of product production (from the beginning of development to the finished product). By applying an integrated approach to solving problems, we save your energy, time and money.

The company specializes exclusively in vacuum and cryogenic equipment and therefore our specialists have extensive technical experience in these areas. They can not only help you choose the right model, but also help in the development of any vacuum system. The company's engineers travel to customers for installation, start-up and maintenance of equipment and staff training.

The company's specialists undergo trainings on maintenance and repair of all types of supplied equipment and therefore can provide flexible support to customers during operation, solving problems both remotely and carrying out authorized repairs in our service center. We hope that you will choose our company as your supplier of vacuum and cryogenic equipment and our cooperation will be long-term.

MORE THAN 5 YEARS IN THIS SEGMENT

We have honed our production and logistics systems and have a large number of contractors and suppliers, which brings our service to a high professional level!

The VacuumTech team successfully develops innovative production systems for thin-film equipment. These systems make it possible to make the final product more cost-effective for the manufacturer and affordable for the consumer, while increasing the quality level and technical characteristics of the product.

577 COMPLETED PROJECTS

We have successfully implemented and completed all related projects:

- production systems of thin-film equipment;

- with space simulation installations;

- high-vacuum pumping stations for various scientific applications;

- various scientific, research and experimental vacuum installations.

Vacuum and cryogenic equipment

OUR PARTNERS

HUBER

We are a leading supplier of high-precision temperature control solutions for research and industry. Worldwide, our products ensure precise temperature control in laboratories, pilot plants and production processes. Our product range offers innovative solutions for almost all tasks in the field of liquid temperature control from -125 to +425 °C. One focus of our product portfolio is the dynamic temperature control systems of the Unistat series.

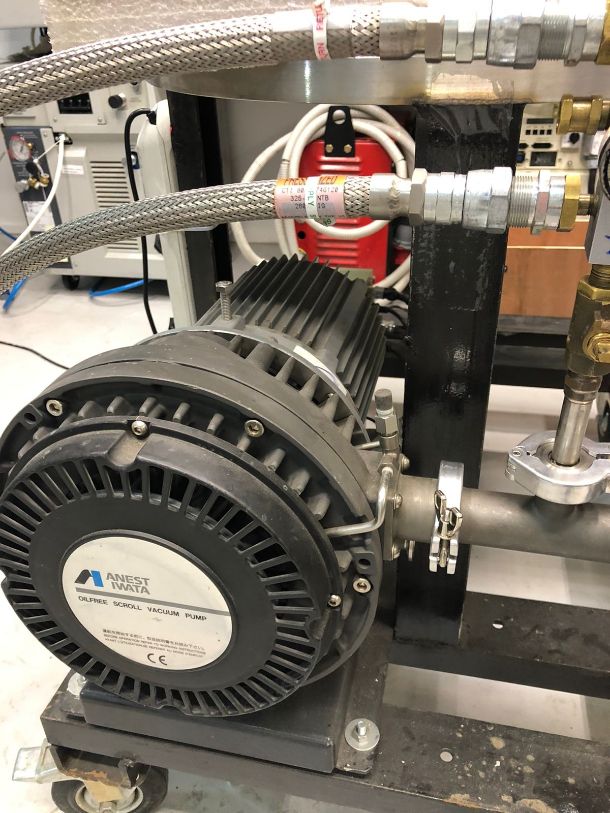

ANEST IWATA

ANEST IWATA in the North America subsidiary of ANEST IWATA Corporation in Japan, which is a leading manufacturer specializing in painting equipment, turnkey coating systems, air compressors and high-end dry vacuum pumps.

As part of the world-class operation we have two market specific divisions within our North American headquarters that strive to exceed the highly advanced needs of North American industries with innovative, state-of-the-art technologies and services.